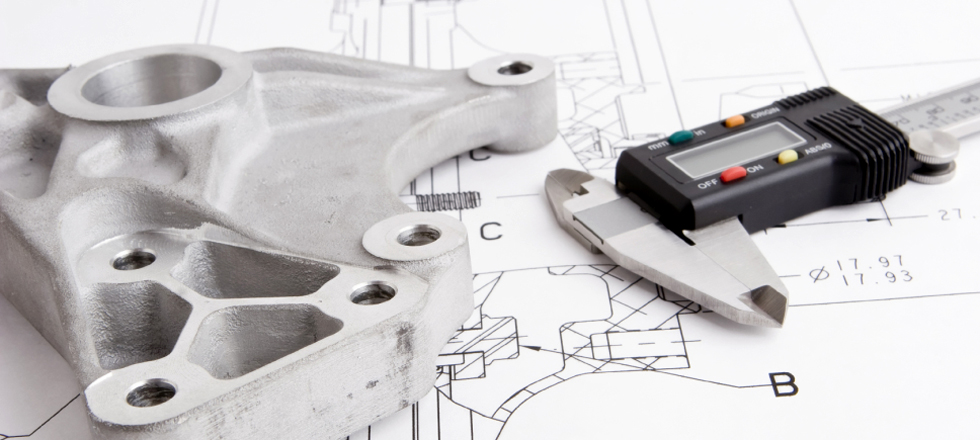

Design & Product Development

The early planning stages of a sourcing project are often decisive for the final outcome. If you get your design right the following production process is way easier than if there are still unsolved design issues.

For this reason, we set up our own in-house design team which can help you with all major aspects of product design and prototyping.

Based on your briefing, design scribbles or reference pictures or design team is going to take over.

We cover the following stages of product design in our China office.

Stages of Product Design:

- Product Scribbling:

Product scribbles help you narrow down your ideas to a more concrete product - Illustrations:

Sometimes an illustrated product with colors makes it easier to envision the final product and thus help in the decision and design modification process - 3D Design:

Our 3D designers will create a realistic 3D image of your product based on your designs or the previous design scribbles which will help you with the fine-tuning of your product and with communicating your idea to the supplier

Depending of the complexity of your product, we offer the following options to create a prototype of your product before going into bulk production. All of them will help fine-tune your product before going into production. That way, a prototype can help finding issues in the design which – if they remain undetected – can become very costly and time-consuming to fix if only discovered during bulk production.

- Hand Moulds

A hand mould is a realistic prototype of your product which is made not using the same machine used for the final production but either design with some softer plastic material by hand or using a special prototyping machine.

Starting with a hand mould helps detect design issues at an an early point so they can still be avoided instead of having to modify the real mould at a later point. - Dummy Samples

A dummy sample is a sample made of the same or a similar material as the final product but at a much lower cost and without all the details of the final products. Again it helps you get a more realistic idea of your future product and detect design issues that can still be modified at this early stage before going into bulk production. - Rapid Prototyping 3D Models

There are different ways of rapid prototyping but the one we most often use is a 3D printer where a laser hardens different layers of a special powder or granulate until you have the shape of your final product. The advantages of a 3D model are the same as above – it helps you avoid design flaws that were previously not detected in illustrations or 3D design files.